Inverter in Generator for Energy Saving

This application introduces frequency inverter in ID fan reconstruction. Inverter not only saves energy, but also improves start-up of motor and fan, prolongs lifetime of equipment.

Introduction

1# unit (coal-fired) is 300MWgenerator with two sets of static blade axial-flow ID fan and YKK800-8-W motor. There is no speed-adjusting device for motor. Air flow is controlled by changing angle of blade. The parameter table is as follows:

In general, the load of the unit varies in the range of 50%~100%. Generator output power varies. Forced air flow and induced air flow of boiler vary correspondingly. ID fan is adjusted by changing angle of blade. Although there is energy-saving to some extent contrast to damper adjustment. The loss is still considerable, especially in the situation of low load. Secondly the slow adjustment of static blade may lead to the load lag correspondingly. Generally, the starting current of asynchronous motor is 8~10 times of the rated current, which may surge the power grid. Big torque also affects lifetime of motor and fan badly.

When the speed of the fan varies, the efficiency varies a little. The flow is directly proportional to speed. Pressure is directly proportional to the square of the speed, and shaft power is directly proportional to the cube of the speed. Furthermore, the shaft power would reduce in cube relation when the speed is down, so does the motor power. Then we know that speed adjusting is the key of energy-saving for fans. It could achieve linear adjustment for ID fan with inverter.

Frequency inverter can optimize the operation of the motor and enhance efficiency greatly to save energy. There were some restrictions before, such as price, reliability, capacity etc. inverter was not widely used. Recently, with the rapid development of power devices, control theory and computer science, declining price of inverter and increasing reliability, MV inverter has been widely used in auxiliary equipment of power plants.

2 inverters in ID fan of 1# unit adjust motor speed to control air flow and pressure. According to the practical situation, operation current of ID fan is just around 140A in full load. We choose model of inverter in conformity with practical current rather than rated power for the consideration of energy-saving. Finally we choose Gozuk inverter. It is voltage source digital control inverter, high-high type, H bridge series connection. Reconstruction was from May to July in 2005, total 40 days. The inverter started to run on 10 July in 2005 with 1# unit together.

Inverter Structure

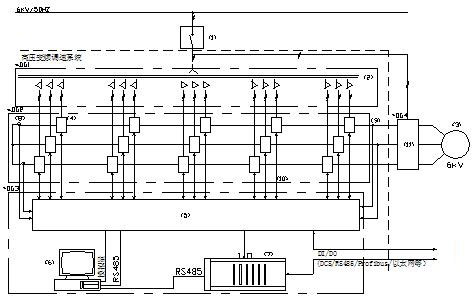

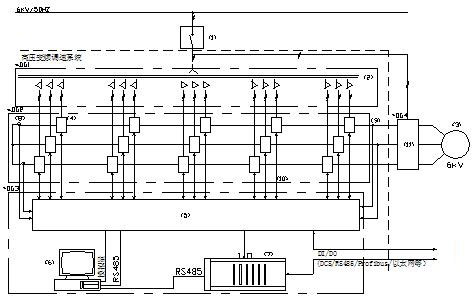

Fig.1 structure of multi-level voltage source inverter

Multi-level voltage source inverter is composed of phase-shifting transformer, power cells and controller. (fig.1)

Ports between inverter and the field

Controller is composed of high speed SCM, HMI and PLC. SCM realizes PWM control and power cell protection. HMI based on Windows CE has friendly touch screen interface, and it also realizes remote control and net control. Inside PLC treats with the logic of digital signals and communicates with the controller system of user. The PLC is Siemens S7-200 which has perfect interface to DCS.

1) The interface between DCS and inverter

There are 11 signals between DCS and inverter. Among the rest, there are 9 digital signals and 2 analog signals.

2) The materials and cables

There are 14 cores in the cable which is used to transport digital signals from inverter to the MC cabinet of the DCS, 4 cores for digital signals from RC cabinet of the DCS to inverter, and another 4 cores for the analog signals between DCS and inverter. 800m cable is needed in DCS inside.

Module used: DCS control module 6DS1412-8RR 2 pieces, 6DS1717-8RR 2 pieces, 6DS1723-8BB 1 piece

Running mode and control logic

Generally, two fans run in variable frequency state. Considering the situation of inverter fault, we prepare two modes:

Frequency inverter is controlled by DCS in manual or auto. In manual mode, operator could adjust pressure by controlling speed of inverter through DCS interface.

1) Allowable conditions of inverter start

Because preconditions of inverter start-up are closing MV switch and start feedback is 1. Original conditions of fan start-up are preserved for inverter start-up.

Ready signal from inverter is another condition.

In commissioning of remote control of inverter, we find there is a considerable impulse on combustion chamber because of high speed set in inverter. Thus when inverter starts, limitation of speed-set must be less than 30%.

In short, there must be three conditions of inverter start:

When inverter of single side fan trips off, it link-closes FD fan of side. Logic of damper and blade keep unchanged.

When inverters of double side fan trip off, because MV switch link close, original boiler link trip keeps unchanged.

The boiler's safe operation is guarantee of plant power. Although the inverter is very reliable, it must make sure boiler can run safely once inverter is in failure. Thus it requires the switch between DOL(direct on line) and inverter. Once a inverter is in failure and it can not recovery immediately, original static blade adjustment is needed. In this case, we must stop one inverter, turn up the other, put the blade into use, and then adjust and modify some parameters by commissioning.

Comprehensive Evaluation

1) Energy efficiency significantly

Below there are some data for comparing.

By comparing the data, at the same circumstances, the average daily consumption of unit 1# is 16431kW.h, others are 32450kW.h. Power saved is 16019kW.h. Power-saving rate is 49.37%.

2) energy-saving calculation

If every fan works 7200 hours in a year and two fans are driven by inverters, the power saved might be 4805700 kW.h. Power price of power is 0.2 yuan/kW.h. cost saved should be 961140yuan(USD141344)

Conclusion

To sum up, inverter widely application in power plants is the trend in future. It not only saves energy significantly, but also has good adjustment ability. Inverter prolongs the lifespan of fans and motors. With the development of high-technology, cost-decreasing, and new design, it simplifies the structure of inverter, reduces components and makes inverter more reliable.

Introduction

1# unit (coal-fired) is 300MWgenerator with two sets of static blade axial-flow ID fan and YKK800-8-W motor. There is no speed-adjusting device for motor. Air flow is controlled by changing angle of blade. The parameter table is as follows:

| TYPE | RATED FLOW (m3/H) | PRESSURE (Pa) |

| AN-28 ID FAN | 928800 | 3196 |

| TYPE | RATED POWER(KW) | RATED VOLTAGE(KV) | RATED CURRENT(A) |

| YKK800-8-W | 2000 | 6 | 254 |

In general, the load of the unit varies in the range of 50%~100%. Generator output power varies. Forced air flow and induced air flow of boiler vary correspondingly. ID fan is adjusted by changing angle of blade. Although there is energy-saving to some extent contrast to damper adjustment. The loss is still considerable, especially in the situation of low load. Secondly the slow adjustment of static blade may lead to the load lag correspondingly. Generally, the starting current of asynchronous motor is 8~10 times of the rated current, which may surge the power grid. Big torque also affects lifetime of motor and fan badly.

When the speed of the fan varies, the efficiency varies a little. The flow is directly proportional to speed. Pressure is directly proportional to the square of the speed, and shaft power is directly proportional to the cube of the speed. Furthermore, the shaft power would reduce in cube relation when the speed is down, so does the motor power. Then we know that speed adjusting is the key of energy-saving for fans. It could achieve linear adjustment for ID fan with inverter.

Frequency inverter can optimize the operation of the motor and enhance efficiency greatly to save energy. There were some restrictions before, such as price, reliability, capacity etc. inverter was not widely used. Recently, with the rapid development of power devices, control theory and computer science, declining price of inverter and increasing reliability, MV inverter has been widely used in auxiliary equipment of power plants.

2 inverters in ID fan of 1# unit adjust motor speed to control air flow and pressure. According to the practical situation, operation current of ID fan is just around 140A in full load. We choose model of inverter in conformity with practical current rather than rated power for the consideration of energy-saving. Finally we choose Gozuk inverter. It is voltage source digital control inverter, high-high type, H bridge series connection. Reconstruction was from May to July in 2005, total 40 days. The inverter started to run on 10 July in 2005 with 1# unit together.

| TYPE | RATED CAPACITY | RATED VOLTAGE | RATED CURRENT |

|

Gozuk Inverter |

2250KVA | 6KV | 220A |

Inverter Structure

Fig.1 structure of multi-level voltage source inverter

Multi-level voltage source inverter is composed of phase-shifting transformer, power cells and controller. (fig.1)

Ports between inverter and the field

Controller is composed of high speed SCM, HMI and PLC. SCM realizes PWM control and power cell protection. HMI based on Windows CE has friendly touch screen interface, and it also realizes remote control and net control. Inside PLC treats with the logic of digital signals and communicates with the controller system of user. The PLC is Siemens S7-200 which has perfect interface to DCS.

1) The interface between DCS and inverter

There are 11 signals between DCS and inverter. Among the rest, there are 9 digital signals and 2 analog signals.

| Number | Code Number of DCS | Character | Name of electrical side | Note |

| 1 | S0701-RD | DI | A fan inverter ready | Allowable signal for start-up |

| 2 | S0701TRS-RME | DI | A fan inverter running | HMI |

| 3 | S0701TRS-RMA | DI | A fan inverter stop | HMI |

| 4 | S0701-W | DI | A fan inverter light fault | HMI |

| 5 | S0701-A | DI | A fan inverter serious fault | HMI |

| 6 | S0701-RE | DI | Breaker enable | Allowable signal for controlling inverter |

| 7 | S0701-FF | DI | Cell bypass | HMI |

| 8 | S0701TRS-ALE | DO | A fan inverter start | From DCS |

| 9 | S0701TRS-ALA | DO | A fan inverter stop | From DCS |

| 10 | C0701TRSG | AI | A fan inverter speed feedback | 24VDC from inverter |

| 11 | C0701TRS | AO | Speed control | 24VDC from DCS |

2) The materials and cables

There are 14 cores in the cable which is used to transport digital signals from inverter to the MC cabinet of the DCS, 4 cores for digital signals from RC cabinet of the DCS to inverter, and another 4 cores for the analog signals between DCS and inverter. 800m cable is needed in DCS inside.

| Number | Signals | Cable starting | Cable ending | Type | Quantity |

| 1 | S0701-RD S0701TRS-RME S0701TRS-RMA S0701-W S0701-A S0701-RE S0701-FF | A fan inverter | MC cabinet of DCS | Control cable KVV22 12×1.5 | 2 2X400m |

| 2 | S0701TRS-ALE S0701TRS-ALA | RC cabinet of DCS | A fan inverter | Control cable KVV22 6×1.5 | 1 1X400m |

| 3 | C0701TRSG C0701TRS | A fan inverter | MC cabinet of DCS | Screen control cable KVVP22/2 6×1.5 | 1 1X400m |

Module used: DCS control module 6DS1412-8RR 2 pieces, 6DS1717-8RR 2 pieces, 6DS1723-8BB 1 piece

Running mode and control logic

Generally, two fans run in variable frequency state. Considering the situation of inverter fault, we prepare two modes:

- One fan works in direct on line and the other works in variable frequency.

- All two fans works in direct on line.

Frequency inverter is controlled by DCS in manual or auto. In manual mode, operator could adjust pressure by controlling speed of inverter through DCS interface.

1) Allowable conditions of inverter start

Because preconditions of inverter start-up are closing MV switch and start feedback is 1. Original conditions of fan start-up are preserved for inverter start-up.

Ready signal from inverter is another condition.

In commissioning of remote control of inverter, we find there is a considerable impulse on combustion chamber because of high speed set in inverter. Thus when inverter starts, limitation of speed-set must be less than 30%.

In short, there must be three conditions of inverter start:

- For ID fan A /B, MV parts S07-1, S08-1 feedback are 1.

- The ready signals S0701-RD, S0801-RD from PLC are 1.

- The speed-set value of inverter C0701TRS, C0801TRS output is less than 30%.

When inverter of single side fan trips off, it link-closes FD fan of side. Logic of damper and blade keep unchanged.

When inverters of double side fan trip off, because MV switch link close, original boiler link trip keeps unchanged.

The boiler's safe operation is guarantee of plant power. Although the inverter is very reliable, it must make sure boiler can run safely once inverter is in failure. Thus it requires the switch between DOL(direct on line) and inverter. Once a inverter is in failure and it can not recovery immediately, original static blade adjustment is needed. In this case, we must stop one inverter, turn up the other, put the blade into use, and then adjust and modify some parameters by commissioning.

Comprehensive Evaluation

1) Energy efficiency significantly

Below there are some data for comparing.

| Date | Unit 1# | Unit 2# | Unit 3# | Unit 4# | ||||

| power consumption (KW·h) | unit consumption (%) | power consumption (KW·h) | unit consumption (%) | power consumption (KW·h) | unit consumption (%) | power consumption (KW·h) | unit consumption (%) | |

| 10th | 10800 | 0.39 | 29520 | 0.58 | 31056 | 0.56 | 31632 | 0.57 |

| 11th | 10800 | 0.25 | 28620 | 0.60 | 30720 | 0.56 | 31248 | 0.57 |

| 12th | 9540 | 0.22 | 32040 | 0.56 | 34608 | 0.57 | 35280 | 0.57 |

| 13th | 15480 | 0.29 | 32760 | 0.59 | 34080 | 0.59 | 34752 | 0.59 |

| 14th | 25380 | 0.40 | 35460 | 0.61 | 33552 | 0.57 | 33456 | 0.57 |

| 15th | 20052 | 0.34 | 38160 | 0.62 | 37056 | 0.60 | 38784 | 0.61 |

| 16th | 22968 | 0.38 | 33120 | 0.60 | 36864 | 0.59 | 38160 | 0.60 |

By comparing the data, at the same circumstances, the average daily consumption of unit 1# is 16431kW.h, others are 32450kW.h. Power saved is 16019kW.h. Power-saving rate is 49.37%.

2) energy-saving calculation

If every fan works 7200 hours in a year and two fans are driven by inverters, the power saved might be 4805700 kW.h. Power price of power is 0.2 yuan/kW.h. cost saved should be 961140yuan(USD141344)

Conclusion

To sum up, inverter widely application in power plants is the trend in future. It not only saves energy significantly, but also has good adjustment ability. Inverter prolongs the lifespan of fans and motors. With the development of high-technology, cost-decreasing, and new design, it simplifies the structure of inverter, reduces components and makes inverter more reliable.

<- - I have an Opinion - ->