Inverter in Power Plant

Tags: inverter, Power Plant

Abstract: The paper introduced the application of MV inverter on fan and pump in the thermal power plant.

Preface

Frequency control is widely used in several fields for its superiority in energy-saving, adjustment precision, adjustment range and easy to communicate with automatic control system. This text is aiming to illustrate its broad prospects by introducing and concluding several success cases.

1. Frequency control of boiler's fan

1.1 Application of the boiler's SA fan

The boiler is circulation boiler which is equipped with ID fan, PA fan, SA fan. The parameters as below:

As is known in boiler's regular service, there are considerable variety in fuel composition, heat load, power load, and seasons. Thus, the air for the boiler varies greatly. However, the fan of boiler is designed according to the maximum air flow in full load. In the mean time, there is certain redundancy for air flow in case of boiler's accident. Generally the power of fan is large. From the statistic, average opening of the wind shield in normal condition, 48% in ID fan, 45% in SA fan. Adjusting shield causes a large quantity of energy waste on overcoming the shield resistance. Plant efficiency is low.

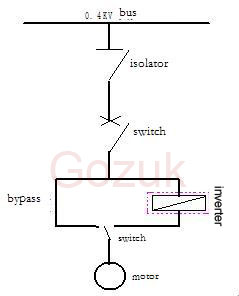

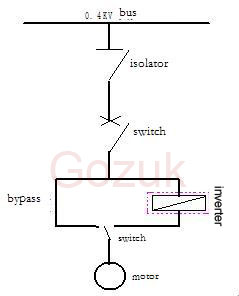

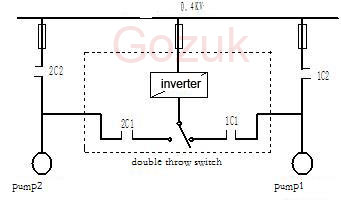

At the end of 2000, we planned to choose SA fan of #1 to reform. Considering the fan redundancy, we purposely chose inverter of 132kW to control the fan of 160kw. The inverter started to run in January 2001. By a long term running, the current of the fan reduces from 135A to 75A, which reaches obvious energy saving and meets the requirement of boiler operation. According to the ammeter, energy saving rate is 45% and the cost is recovered in one year. Furthermore, the motor is improved in thermo of start-up, adjustment, controlling and operation. For the perfect benefit, we reform the fans in the other unit later. In design of bypass circuit, we choose double-throw switch in manual as its low-cost, good performance, easy to connect and install and high reliability. The circuit is below:

2. Application of inverter on ID fan

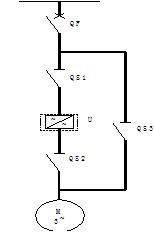

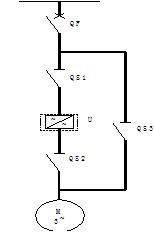

After the success inverter application of SA fans, we see enormous potential benefit. In 2002, we chose ID fan of #3 to reform. By comparing and studying, we consider vector inverter as the first choice as its high performance, reasonable price, widely using and good after-sale service. The vector inverter is Multi-level voltage source inverter with the technology of cascade-connected power cells. The rectifier is 30-pulses, diode three-phase full bridge, IGBT inverter bridge series output. In order to fully ensure the system reliability, a bypass device is configured with MV inverter. When inverter is broken, motor can be manually switched to direct on line. The bypass circuit is composed of 3 MV disconnecting switches QS1, QS2 and QS3. When the motor is driven by inverter, QS1, QS2 are closed and QS3 is open; when the motor is in direct on line, QS3 is closed, QS1,QS2 are open.

The inverter is remote controlled through the start/stop buttons, switches for speed adjusting on the operation board of boiler, and it is able to communicate with DCS. To make operation convenience, there are many functions, such as alarm instruction, fault instruction, ready state, bypass, running, MV allowable, emergency stop, speed set, actual speed etc.

Period of commissioning, installation and tests was 4 days. We also made some dynamic tests such as fully-loaded, system threshold vibration test, bus voltage-hunting test, interlock test between MV switch and inverter and continuous 72 hours preoperation.

According to the data, the current of the fan reduces from 25A to 15A, which means around 130 kW/h is saved. The energy-saving ratio is more than 50% and the benefit is obvious. Due to perfect economic benefit, we would reform other devices.

3. Application of inverter on pump

Plant consumes daily water about 6000~7000t which mainly is used as water-refining, industrial water, water for life. There are three pumps in the pump room. The parameters are below:

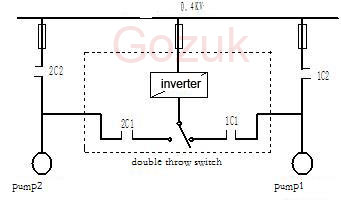

On the one hand, 3# pump force is too small to meet the demand of the consumption. Other 2 pumps force is too large to control, and this leads to motor frequent stop/start. On the other hand, the ideal method for purifying is water-supply continuously which is high efficiency and good effect. If the pump frequently stops/starts, it may lead to water break. When water conditioner stops, the plastic pipe is easy to be aged for exposing in the sunshine long term. If the water conditioner stops too long , it should be rewashed so that water is wasted considerably. Furthermore, it is 600 meters long between the pump room and the water conditioner, and the pipe is laid too shallow to be easy burst in winter. All above are caused by long time water-stop, sleeper in pipe, water freezing in low temperature. Thus we plan to reform for 1#, 2# pump with inverter.

4. Problems in technology reform

4.1 The boilers' security is basic guarantee for the plant. Although the inverter is reliable, once it faults, system must make sure boiler work well. Thus, bypass circuit is required. Generally, if manual bypass meets demand, it is better not to choose automatic bypass cabinet. For normal low-power motors, manually/automatic bypass by double throw switches is ideal.

4.2 For large inertia-load motors (boilers' ID fans), there might be flexural resonance. Once it happens during operation, fans and motor might be damaged seriously. Thus the critical speed must be calculated and some measure must be done, such as set frequency leap point, soft connection, add rubber.

4.3 After reform with inverter, if inverter works below 25Hz long time, with speed reducing, motor heat reduces. Thus, temperature of motor declines and it works normally without overheating.

4.4 The inverter can not transfer power back to grid, thus it requires that QS2 and QS3 can not switch off at the same time for ID fan.

4.5 Low-voltage inverter which is smaller, easy to choose the installation site in technology reform. But for medium-voltage inverter which is much larger, generally composed of 4-5 cabinets, needs a room. Thus the site can not be too far from the motor. It requires a better circumstances for inverter stable and reliable operation. Temperature must be between 0 and 40℃. Air conditioning should be equipped if temperature is too high. At the same time, room inside must be clean, without dust, corrosive and explosive gas.

4.6 Make sure reliable earth. To avoid signal interfere, user should make independent earth system. Earth resistor is less than 4. signal wire to inverter must be screen cable. One terminal should be well earthed.

4.7 Considering practical operation situation, user can choose lower power inverter. For example, we use 132kW inverter to control 160kW motor in reform of SA fan.

Conclusion

With the development of power electronics, the inverters performance is improving. In thermal power plant, there are a large number of pumps and fans, and inverter is widely used in technology reform for energy saving.

Preface

Frequency control is widely used in several fields for its superiority in energy-saving, adjustment precision, adjustment range and easy to communicate with automatic control system. This text is aiming to illustrate its broad prospects by introducing and concluding several success cases.

1. Frequency control of boiler's fan

1.1 Application of the boiler's SA fan

The boiler is circulation boiler which is equipped with ID fan, PA fan, SA fan. The parameters as below:

- ID fan: Y400-6, 400kW, 6kV, 47.3A

- PA fan: Y355-4, 250kW, 6kV, 29.3A

-

SA fan: Y315L1-4, 160kW, 380V, 289A

|

Average current |

Average opening |

Maximum opening |

Maximum current |

Minimum current |

|

PA Fan |

||||

|

21 A |

50% |

55% |

23 A |

20 A |

|

ID Fan |

||||

|

25 A |

48% |

50% |

28 A |

24 A |

|

SA Fan |

||||

|

135 A |

45% |

50% |

140 A |

130 A |

As is known in boiler's regular service, there are considerable variety in fuel composition, heat load, power load, and seasons. Thus, the air for the boiler varies greatly. However, the fan of boiler is designed according to the maximum air flow in full load. In the mean time, there is certain redundancy for air flow in case of boiler's accident. Generally the power of fan is large. From the statistic, average opening of the wind shield in normal condition, 48% in ID fan, 45% in SA fan. Adjusting shield causes a large quantity of energy waste on overcoming the shield resistance. Plant efficiency is low.

At the end of 2000, we planned to choose SA fan of #1 to reform. Considering the fan redundancy, we purposely chose inverter of 132kW to control the fan of 160kw. The inverter started to run in January 2001. By a long term running, the current of the fan reduces from 135A to 75A, which reaches obvious energy saving and meets the requirement of boiler operation. According to the ammeter, energy saving rate is 45% and the cost is recovered in one year. Furthermore, the motor is improved in thermo of start-up, adjustment, controlling and operation. For the perfect benefit, we reform the fans in the other unit later. In design of bypass circuit, we choose double-throw switch in manual as its low-cost, good performance, easy to connect and install and high reliability. The circuit is below:

2. Application of inverter on ID fan

After the success inverter application of SA fans, we see enormous potential benefit. In 2002, we chose ID fan of #3 to reform. By comparing and studying, we consider vector inverter as the first choice as its high performance, reasonable price, widely using and good after-sale service. The vector inverter is Multi-level voltage source inverter with the technology of cascade-connected power cells. The rectifier is 30-pulses, diode three-phase full bridge, IGBT inverter bridge series output. In order to fully ensure the system reliability, a bypass device is configured with MV inverter. When inverter is broken, motor can be manually switched to direct on line. The bypass circuit is composed of 3 MV disconnecting switches QS1, QS2 and QS3. When the motor is driven by inverter, QS1, QS2 are closed and QS3 is open; when the motor is in direct on line, QS3 is closed, QS1,QS2 are open.

The inverter is remote controlled through the start/stop buttons, switches for speed adjusting on the operation board of boiler, and it is able to communicate with DCS. To make operation convenience, there are many functions, such as alarm instruction, fault instruction, ready state, bypass, running, MV allowable, emergency stop, speed set, actual speed etc.

Period of commissioning, installation and tests was 4 days. We also made some dynamic tests such as fully-loaded, system threshold vibration test, bus voltage-hunting test, interlock test between MV switch and inverter and continuous 72 hours preoperation.

According to the data, the current of the fan reduces from 25A to 15A, which means around 130 kW/h is saved. The energy-saving ratio is more than 50% and the benefit is obvious. Due to perfect economic benefit, we would reform other devices.

3. Application of inverter on pump

Plant consumes daily water about 6000~7000t which mainly is used as water-refining, industrial water, water for life. There are three pumps in the pump room. The parameters are below:

|

|

Power |

Rated Current (A) |

Flow (t) |

|

1#pump |

37kW |

70.4 |

400 |

|

2#pump |

37kW |

70.4 |

400 |

|

3#pump |

18.5kW |

36.5 |

200 |

On the one hand, 3# pump force is too small to meet the demand of the consumption. Other 2 pumps force is too large to control, and this leads to motor frequent stop/start. On the other hand, the ideal method for purifying is water-supply continuously which is high efficiency and good effect. If the pump frequently stops/starts, it may lead to water break. When water conditioner stops, the plastic pipe is easy to be aged for exposing in the sunshine long term. If the water conditioner stops too long , it should be rewashed so that water is wasted considerably. Furthermore, it is 600 meters long between the pump room and the water conditioner, and the pipe is laid too shallow to be easy burst in winter. All above are caused by long time water-stop, sleeper in pipe, water freezing in low temperature. Thus we plan to reform for 1#, 2# pump with inverter.

4. Problems in technology reform

4.1 The boilers' security is basic guarantee for the plant. Although the inverter is reliable, once it faults, system must make sure boiler work well. Thus, bypass circuit is required. Generally, if manual bypass meets demand, it is better not to choose automatic bypass cabinet. For normal low-power motors, manually/automatic bypass by double throw switches is ideal.

4.2 For large inertia-load motors (boilers' ID fans), there might be flexural resonance. Once it happens during operation, fans and motor might be damaged seriously. Thus the critical speed must be calculated and some measure must be done, such as set frequency leap point, soft connection, add rubber.

4.3 After reform with inverter, if inverter works below 25Hz long time, with speed reducing, motor heat reduces. Thus, temperature of motor declines and it works normally without overheating.

4.4 The inverter can not transfer power back to grid, thus it requires that QS2 and QS3 can not switch off at the same time for ID fan.

4.5 Low-voltage inverter which is smaller, easy to choose the installation site in technology reform. But for medium-voltage inverter which is much larger, generally composed of 4-5 cabinets, needs a room. Thus the site can not be too far from the motor. It requires a better circumstances for inverter stable and reliable operation. Temperature must be between 0 and 40℃. Air conditioning should be equipped if temperature is too high. At the same time, room inside must be clean, without dust, corrosive and explosive gas.

4.6 Make sure reliable earth. To avoid signal interfere, user should make independent earth system. Earth resistor is less than 4. signal wire to inverter must be screen cable. One terminal should be well earthed.

4.7 Considering practical operation situation, user can choose lower power inverter. For example, we use 132kW inverter to control 160kW motor in reform of SA fan.

Conclusion

With the development of power electronics, the inverters performance is improving. In thermal power plant, there are a large number of pumps and fans, and inverter is widely used in technology reform for energy saving.

<- - I have an Opinion - ->